The basic process of clothing production includes fabrics, accessories into the factory inspection, cutting, LOGO production, sewing, keyhole nail button, ironing, clothing inspection, clothes in addition to the normal inspection, but also to the city fiber indicators testing, the test can be qualified before packaging warehousing delivery, packaging and warehousing six processes.

1: Fabric inspection of accessories and accessories

After the fabric enters the factory, the quantity count and the appearance and internal quality inspection should be carried out. Only when they meet the production requirements can they be put into operation. The quality of fabrics is an important part of controlling the quality of clothing products. The inspection and determination of the incoming fabric can effectively improve the quality rate of clothing. Humen women's clothing is very famous, not only is the good style, but also mainly because of the excellent production. Si Yinghong's clothes, in the circle is still very famous, this is recognized in the industry, I do not need to say more.

Material inspection includes elastic band shrinkage, adhesion adhesion, zipper smoothness and so on. For materials that can not meet the requirements will not be put into use, many customers often ask us clothes shrinkage, pilling problem, in fact, now, many fabrics before making clothes, are shrinkage, shrinkage processing, although do not guarantee 100%, but the process is more than one step than before.

2: Technical preparation

Technical preparation is an important means to ensure the smooth mass production and the final product to meet customer requirements.

Before mass production, the technical preparation before production. Technical preparation includes three contents: process list, the formulation of sample samples and the production of sample clothes.

Process sheet is a guiding document in garment processing. It puts forward detailed requirements on the specifications, sewing, ironing, and packaging, etc., and also makes clear the details of the collocation of garment auxiliary materials and the density of sewing tracks. All processes in the garment processing should be carried out strictly according to the requirements of the process sheet.

Sample production requires accurate size and complete specifications. The contour lines of the relevant parts coincide accurately. The clothing number, parts, specifications and quality requirements should be marked on the sample, and the sample composite seal should be affixed to the relevant splicing place. After the completion of the process sheet and sample formulation, the production of small batch sample clothes can be carried out, and the nonconformity points can be corrected according to the requirements of customers and the process, and the process difficulties can be solved, so that the mass flow operation smoothly.

The sample has become one of the important inspection bases after the customer.

3: Cut

Before cutting clothes, discharging materials should be drawn according to the sample plate. "Complete, reasonable and saving" is the basic principle of discharging materials. LOGO production has a variety of processing methods, such as embroidery characters, screen printing, hot transfer printing, weaving labels and so on.

Sewing is the central process of garment processing. Garment sewing can be divided into machine sewing and hand sewing according to the style and craft style. In the sewing process in the implementation of the flow operation. This is so familiar that many clothing store owners will step on their own sewing machines.

4: Lock eye nail buckle

Lock hole and nail buckle in general clothing production are usually made by machine. According to its shape, button hole is divided into flat and eye hole according to its shape, commonly known as sleeping hole and pigeon eye hole. Sleeping holes are mostly used in shirts, skirts, pants and other thin clothing materials. Pigeon eye holes are mostly used in jackets, suits and other thick fabrics on the coat.

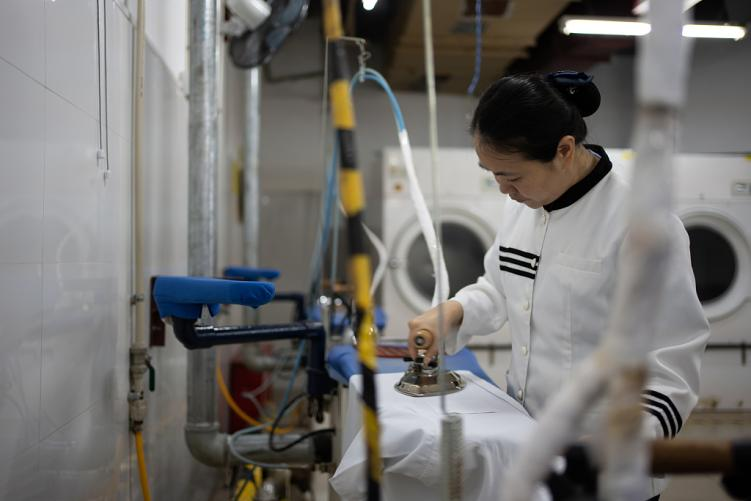

5: The whole hot

Clothing through the ironing to make its appearance smooth, accurate size. When ironing, the lining plate is put into the garment to keep the product maintain a certain shape and specifications. The size of the lining plate is slightly larger than that required by the garment, in order to prevent the size after the shrinkage is too small, the temperature of ironing is generally controlled between 180℃ ~200℃, not easy to burn yellow, coking.

6: clothing clothing inspection, packaging

Garment inspection is the last process for clothing to enter the sales market, so it plays a decisive role in the process of clothing production. Because there are many factors affecting the quality of garment inspection, garment inspection is an important link in the management chain of garment enterprises.

Correct inspection view is very important. Quality inspection refers to the measurement, inspection, test and measure of one or more characteristics of a product or service in a certain method, and comparing the measurement results with the evaluation criteria to determine the quality of each product or service, and whether the batch of the whole product or service is qualified or not. Compared with the required quality, the nature of the products produced will be uneven, there is a certain gap. For this gap, the inspector needs to judge whether the product is qualified or not according to certain standards. The usual standards are: the gap within the allowable range is considered to be qualified; the gap beyond the allowable range is considered to be unqualified:

Post time: Aug-28-2023